Understanding Rapid Prototyping

Definition and Core Principles

Rapid prototyping is a product development method that quickly creates physical models or digital versions of a design. The goal is to test ideas, functions, and design features early in the development process. This approach helps teams identify potential problems, gather feedback, and make improvements before moving into full production. At its core, rapid prototyping focuses on speed, flexibility, and iteration to accelerate innovation and reduce risks.

Key Technologies in Rapid Prototyping

Several technologies power rapid prototyping, offering a range of options depending on the project’s needs:

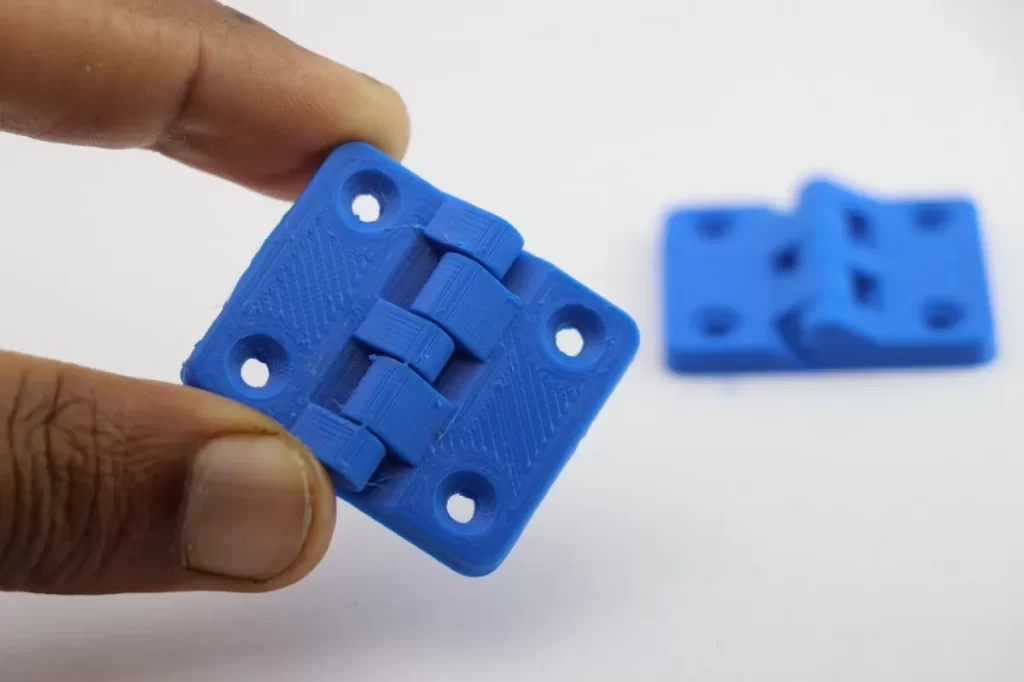

- 3D Printing Services: These create prototypes layer by layer using materials like plastic or resin, perfect for complex shapes and fast turnaround.

- CNC Machining: A subtractive process using CNC machines to carve parts from solid materials, ideal for high precision and strong functional prototypes.

- Additive Manufacturing: Similar to 3D printing but includes broader methods such as selective laser sintering or stereolithography.

- Low-Fidelity and High-Fidelity Prototyping: These refer to the prototype’s level of detail—from simple, rough models for concept testing to detailed, functional versions that closely mimic the final product.

Types of Prototypes

Understanding the different prototype types helps choose the right approach:

- Concept Prototypes: Basic models to explore ideas quickly.

- Functional Prototypes: Used to test feasibility and performance.

- Visual Prototypes: Focus on appearance and ergonomics.

- User Experience Prototypes: Common in UX/UI design to refine software interfaces and interactions.

Rapid prototyping combines these elements to meet diverse project needs, helping teams move from concept to market-ready products efficiently.

Benefits of Rapid Prototyping

Rapid prototyping brings several clear benefits that make it a game-changer for product development.

Speed and Efficiency

One of the biggest perks is how fast it moves the process along. Instead of waiting weeks or months for a traditional prototype, rapid prototyping—using CNC prototyping or 3D printing services—can create models in days or even hours. This quick turnaround lets teams test ideas and make changes on the fly, speeding up the entire product development process.

Cost Savings

Cutting down on time means cutting costs. Rapid prototyping reduces the need for expensive tooling and lowers material waste. Plus, by catching design issues early, it prevents costly mistakes later in production. That’s a big win for both startups and established companies aiming to manage budgets smartly.

Enhanced Innovation

Having a physical model early on sparks creativity. When teams can see and touch prototypes, they get better insights and spot opportunities to improve designs. This hands-on approach encourages rapid iteration design, helping bring fresh, innovative ideas to life faster.

Improved Collaboration

Rapid prototyping also boosts teamwork. Whether it’s product designers, engineers, or clients, everyone can provide feedback on actual prototypes rather than just drawings. This real-world focus makes communication clearer and collaboration smoother across all phases of manufacturing and prototype manufacturing.

In short, rapid prototyping delivers speed, savings, innovation, and teamwork that really power up product development in today’s fast-paced market.

Applications of Rapid Prototyping Across Industries

Rapid prototyping plays a crucial role in many fields, speeding up product development and improving design accuracy.

Manufacturing and Product Design

In manufacturing, rapid prototyping lets you quickly turn ideas into physical models using CNC prototyping and 3D printing services. This helps test form, fit, and function before moving to full production. It’s great for spotting design flaws early, saving time and money in the product development process.

Medical and Healthcare

Healthcare benefits from rapid prototyping by creating custom implants, prosthetics, and surgical models. Additive manufacturing allows precise, patient-specific parts that improve treatment outcomes. Quick iterations mean doctors and engineers can refine designs faster.

Software and UX/UI Design

In software, rapid prototyping focuses on UX/UI prototyping tools. Low-fidelity and high-fidelity prototyping help teams visualize and test user interfaces early. This approach streamlines feedback and reduces costly redesigns later in development.

Robotics and Automation

Robotics relies on rapid prototyping to build and test parts like custom sensors or machine components with CNC machining and prototype manufacturing. It supports rapid iteration design, helping engineers enhance robot performance faster.

How HYCNC Supports These Industries

At HYCNC, we provide reliable CNC service and custom prototyping tailored to your industry needs. Whether you’re in product design, healthcare, software, or robotics, our precision CNC prototyping and 3D printing services help you move from concept to reality faster and with better quality. We focus on design for manufacturability and speed without compromising accuracy, giving your project a critical edge in the competitive US market.

The Rapid Prototyping Process with HYCNC

Step-by-Step Breakdown

At HYCNC, our rapid prototyping process is designed to be straightforward and efficient, helping you move from idea to prototype fast:

- Initial Consultation: We discuss your project needs, goals, and timeline to tailor the prototype approach.

- Design Review: Share your CAD files or sketches. We review for design for manufacturability and suggest improvements.

- Material Selection: Choose from a range of materials suited for CNC prototyping or 3D printing services, balancing durability, cost, and function.

- Prototype Manufacturing: Using advanced CNC machining and additive manufacturing, we create your prototype with precision.

- Quality Check: Each prototype undergoes inspection to ensure it meets your specs and quality standards.

- Rapid Iteration: Need changes? We quickly update the design and produce the next version, supporting rapid iteration design.

- Delivery and Support: Fast shipping and ongoing communication to keep your project on track.

Why Choose HYCNC

- Expertise in CNC Prototyping: We specialize in accurate CNC service, ensuring your prototype matches your vision.

- Wide Range of Technologies: From CNC machining to 3D printing, we offer versatile options to meet any project need.

- Local and Responsive: Based in the US, we understand local market demands and provide timely communication.

- Competitive Pricing and Speed: Our process minimizes cost without compromising quality, delivering your prototype swiftly.

- Support Across Industries: Whether manufacturing, healthcare, or robotics, we tailor solutions to your sector.

If you want to explore how we can boost your product development process with reliable prototype manufacturing, check our rapid tooling services to learn more.

Choosing the Right Rapid Prototyping Partner

Picking the right partner for rapid prototyping can make or break your project. Here are key factors to consider:

-

Experience and Expertise: Look for a provider with a strong track record in CNC prototyping, 3D printing services, and product development processes. They should understand design for manufacturability and offer both low-fidelity and high-fidelity prototyping options.

-

Technology and Capabilities: Ensure they have advanced additive manufacturing tools and CNC machining capabilities that fit your project needs. This flexibility helps with rapid iteration design and smooth prototype manufacturing.

-

Turnaround Time: Speed is essential in rapid prototyping. Find a partner that can deliver fast without sacrificing quality.

-

Communication and Support: You want a partner that collaborates well and provides clear updates throughout the process, improving your overall workflow.

-

Quality and Reliability: Check for quality certifications and customer reviews to ensure consistent results.

At HYCNC, we combine all these factors to give you a competitive edge. Our precision CNC service, state-of-the-art rapid tooling, and 3D printing expertise help streamline your product development process. We focus on delivering high-quality prototypes quickly to keep your innovation on track. Plus, our responsive team works closely with you to solve challenges and optimize designs from start to finish. If you’re ready to move fast and build better, HYCNC is here to help.

For more on how we support rapid prototyping, check out our rapid tooling services.

Common Challenges and How to Overcome Them

Rapid prototyping speeds up the product development process, but it’s not without its challenges. Here are some common issues and how you can tackle them effectively.

Design Errors

Even with fast iterations, design mistakes can slip through. To avoid costly reworks:

- Use low-fidelity prototyping early to test basic ideas.

- Run regular reviews with your team to catch issues before moving to high-fidelity prototyping.

- Leverage tools and software that support rapid iteration design to make quick adjustments.

Material Selection

Choosing the right material is crucial for a prototype that performs well and reflects the final product. To make smart choices:

- Understand the properties your prototype needs, like strength, flexibility, or heat resistance.

- Work with your CNC prototyping or 3D printing services provider to get recommendations.

- Test different materials early in the process to find the best fit.

Balancing Speed and Quality

Rushing prototypes can lead to poor quality, but going too slow defeats the purpose. To find the right balance:

- Set clear goals for each prototype—sometimes speed matters more than perfection.

- Use a mix of additive manufacturing for quick models and CNC machining for precise, functional parts.

- Plan your workflow to allow time for essential quality checks without slowing down progress.

By addressing these challenges head-on, you can make the most of rapid prototyping to create better products faster.

Future Trends in Rapid Prototyping

Rapid prototyping is evolving fast, and staying ahead means keeping an eye on key trends shaping the future.

Advancements in Technology

New tech like improved 3D printing services and smarter CNC prototyping are making prototypes more precise and faster to produce. Additive manufacturing is becoming more versatile, allowing for complex designs with less waste. Expect better materials and faster machines that speed up the product development process without sacrificing quality.

Sustainability

Sustainability is a big deal now. More companies look for eco-friendly materials and processes during prototype manufacturing. Using recycled or biodegradable materials, along with energy-efficient machines, is becoming standard. This reduces environmental impact while still delivering quick, reliable prototypes.

Integration with Agile Development

Rapid prototyping fits perfectly with Agile methods. Quick turnaround on low-fidelity prototyping and high-fidelity prototyping lets teams test ideas and make changes fast. Combining prototyping with Agile means smoother collaboration between designers, engineers, and end-users. It helps reduce errors and speeds up time to market.

Keeping these trends in mind, choosing a partner like HYCNC, which embraces new tech and sustainable methods, ensures your projects stay competitive and efficient.

FAQs

What is rapid prototyping?

Rapid prototyping is a fast way to turn your product ideas into physical or digital models. It helps you test and improve designs early in the product development process.

How does CNC prototyping fit into rapid prototyping?

CNC prototyping uses computer-controlled machines to create precise parts quickly. It’s great for producing high-quality prototypes that need to replicate real product features closely.

Can rapid prototyping save my business money?

Yes. By catching design issues early, rapid prototyping reduces costly changes during full production. It also speeds up the product development cycle, saving time and resources.

What types of prototypes can I create?

You can create low-fidelity prototypes for simple design tests or high-fidelity prototypes that closely match the final product, using methods like 3D printing services or CNC machining.

Is rapid prototyping useful for software and UX/UI design?

Absolutely. Rapid iteration design with UX/UI prototyping tools lets you quickly refine user experiences before launch.

How do I choose the right rapid prototyping partner?

Look for experience in your industry, quality CNC services, quick turnaround times, and strong communication. HYCNC offers all these, plus local support tailored to U.S. businesses.

What challenges should I expect?

Design errors, material selection, and balancing speed with quality can be tricky. Working with experts like HYCNC helps you navigate these issues smoothly.

What’s next for rapid prototyping technology?

Expect advancements in additive manufacturing, more sustainable materials, and tighter integration with agile development to keep speeding things up.