What Is EDM Machining

If you’ve ever wondered how manufacturers shape some of the hardest materials with extreme precision, EDM machining might be the answer. EDM, or Electrical Discharge Machining, is a non-traditional machining process that removes material using controlled electrical discharges—basically tiny sparks—rather than physical cutting tools. This makes it perfect for complex shapes and materials that are tough to machine with regular CNC processes.

At its core, EDM involves three main components:

- Electrode: The tool that generates the sparks

- Workpiece: The material being machined

- Dielectric fluid: An insulating liquid that helps control the sparks and cools the process

There are two primary types of EDM:

- Die-sinking EDM: Uses shaped electrodes to create cavities and intricate geometries

- Wire EDM: Employs a thin wire as the electrode to cut precise contours and shapes through the material

One of the standout advantages of EDM is its incredible precision. Because there’s no physical contact during the process, you get smooth surface finishes and tight tolerances that are hard to achieve with traditional machining. At HYCNC, we leverage this precision to meet the demanding needs of industries requiring flawless components.

How Does EDM Machining Work

EDM machining removes material using controlled electrical discharges instead of traditional cutting. Here’s how the process works step-by-step:

- Setup: The workpiece and electrode are submerged in a dielectric fluid, usually oil or deionized water. This fluid acts as an insulator and coolant.

- Electrical Discharge: A series of rapid electrical sparks jump between the electrode and the workpiece, vaporizing tiny bits of metal.

- Material Removal: Each spark removes microscopic layers, shaping the workpiece with high precision without physical contact.

- Flushing: The dielectric fluid flushes away the eroded particles, keeping the process clean and efficient.

- Repeat: This cycle continues until the desired shape and surface finish are achieved.

Key parameters in EDM machining include pulse duration, current intensity, and spark frequency, which all affect the cutting speed and surface roughness. Materials must be electrically conductive—common choices include tool steels, hard metals, and exotic alloys.

At HYCNC, we use advanced EDM equipment with real-time monitoring and optimized controls. This means faster cycle times, better accuracy, and superior surface quality compared to older EDM technology. Our machines handle both wire EDM and die-sinking EDM, delivering consistent results across complex geometries and tough materials.

For more on our precision capabilities, check out our precision machining services.

Benefits of EDM Machining

EDM machining offers impressive precision and tight tolerances, making it perfect for parts that demand exact dimensions. It’s especially useful when working with hard materials like tool steel or carbide, which can be tough to machine using traditional methods.

One major advantage of EDM is that it removes material without any physical contact. This means no cutting forces or tool pressure, reducing the risk of warping or damaging delicate parts. The result is consistent surface quality with minimal roughness, ideal for applications where surface finish matters.

At HYCNC, we maximize these benefits by using advanced wire EDM and die-sinking EDM equipment. This lets us deliver high-quality parts with reliable accuracy and smooth finishes, perfect for industries requiring precision machining. Our team tailors EDM processes to meet your specific needs, ensuring optimal results every time.

Learn more about our precision machining capabilities to see how EDM fits into your next project.

Applications of EDM Machining

EDM machining is a go-to method across many industries that require precision and complex shapes. At HYCNC, we’ve supported sectors like aerospace, automotive, medical, and tool and die manufacturing with top-quality EDM services.

Industries Served

- Aerospace: Creating tough, heat-resistant parts that demand exact dimensions

- Automotive: Precision components for engines, molds, and specialized parts

- Medical: Delicate tools and implants made from hard-to-machine materials

- Tool and Die: Intricate dies and molds with tight tolerances

Real-World Examples and HYCNC Experience

We’ve worked on projects ranging from custom surgical tools to aerospace components, handling both simple and highly complex designs. Our expertise means better outcomes whether you need prototypes or production parts.

Batch Sizes and Production Volumes

- Small batches or prototypes with quick turnaround

- Medium to large production runs with consistent quality

- Flexible to meet the demands of various industries and project volumes

If you’re looking for reliable EDM or related services, you can also explore our precision machining and CNC machining offerings for a full range of solutions.

EDM Machining vs Traditional CNC Machining

When comparing EDM machining to traditional CNC machining, it’s important to understand how each process fits different needs.

Material and Geometry Suitability

EDM works best on very hard materials like tool steel and hardened alloys that are tough to cut with regular tools. It’s ideal for complex shapes, fine details, and thin walls because it removes material using electrical sparks without physical contact.

Traditional CNC machining is great for a wide range of materials and faster material removal but struggles with extremely hard metals or highly intricate geometries that risk tool wear or breakage.

When to Choose EDM

Use EDM when you need high precision with tight tolerances, especially for hard metals.

Choose EDM for parts where delicate features or sharp corners matter, such as molds, dies, or aerospace components.

EDM also excels when surface finish quality is critical or when the geometry is too complex for conventional cutting.

HYCNC’s Integrated Machining Solutions

At HYCNC, we combine both EDM and traditional CNC machining to deliver efficient, cost-effective results. Our expertise in precision machining means your project gets the right process at every stage—from initial rough cuts on our CNC machines to final details with wire or die-sinking EDM. That way, you get the best of both worlds: fast turnaround and unmatched accuracy.

For more on our CNC capabilities, check out our CNC machining and precision machining services.

Why Choose HYCNC for EDM Machining

At HYCNC, we bring together deep expertise and cutting-edge technology to deliver top-quality EDM machining services tailored to your needs. Our team understands the unique challenges of electrical discharge machining and applies advanced methods to ensure precision and reliability in every project.

We offer custom solutions designed to match your specific material and design requirements. Whether you need wire EDM or die-sinking EDM, we optimize the process for tight tolerances and excellent surface finishes. Plus, our strict quality assurance ensures that every part meets your exact standards before it leaves our facility.

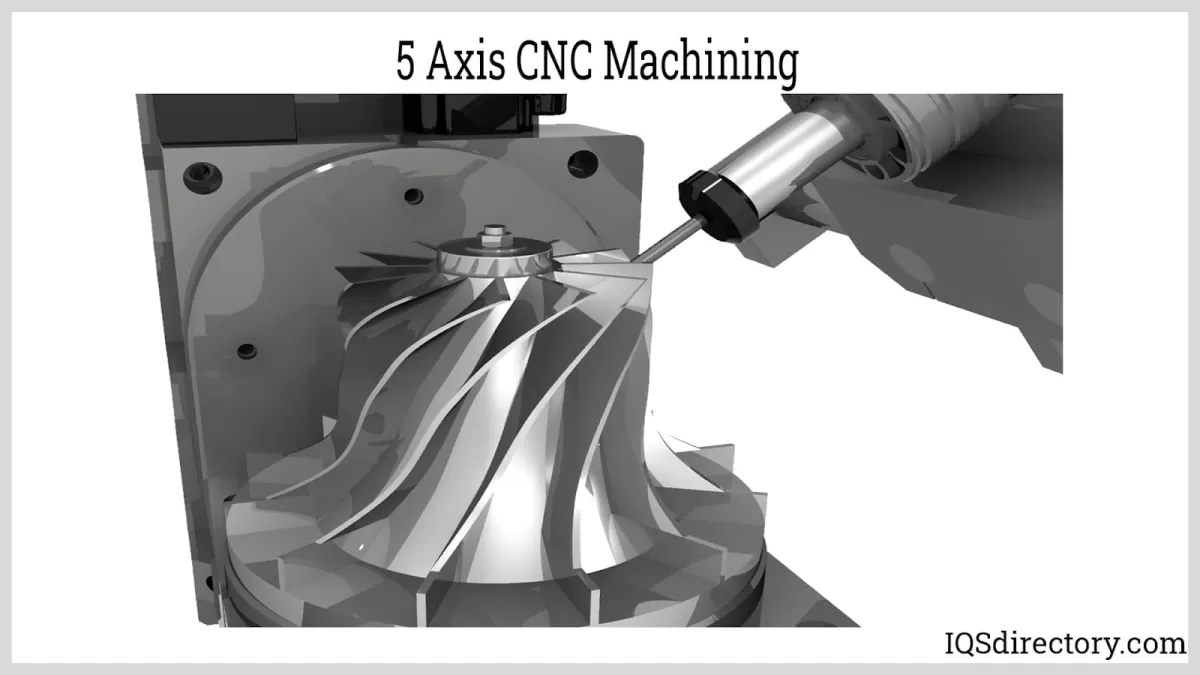

Beyond EDM, HYCNC provides a range of complementary CNC processing services, including precision machining and 5-axis CNC machining, making us a one-stop partner for your advanced manufacturing needs.

Reach out today to learn how HYCNC’s EDM machining can improve your production quality and efficiency. Let’s work together to get your project done right.

Challenges and Solutions in EDM Machining

EDM machining comes with its own set of challenges, but knowing them upfront helps us tackle them efficiently. Here are the most common hurdles we face:

-

Slower Process

Compared to traditional CNC machining, EDM can be slower, especially for large volumes or deep cuts.

-

Conductivity Needs

EDM only works on electrically conductive materials. That limits the types of materials you can machine.

-

Debris and Fluid Management

The process generates tiny particles and relies on dielectric fluid to cool and flush debris. Managing these is critical to avoid tool wear and maintain surface quality.

How We Solve These Challenges at HYCNC

-

Advanced Toolpath Strategies

We use optimized toolpaths to speed up machining without sacrificing precision. This improves material removal rates and reduces cycle times.

-

Real-Time Monitoring

Our EDM equipment comes with real-time sensors that track electrical discharges and fluid conditions. This helps prevent problems before they cause downtime.

-

Optimized Parameters

We fine-tune pulse timing, discharge energy, and dielectric fluid flow for each job. This ensures better surface roughness and extends electrode life.

By combining these technical solutions with our skilled team’s experience, HYCNC minimizes EDM’s downsides while maximizing the precision and quality you expect.

The Future of EDM Machining

EDM machining is evolving fast with new trends shaping the future of precision manufacturing. Hybrid machining, which combines EDM with traditional CNC methods, is gaining ground. This approach boosts efficiency and expands what we can achieve with hard materials.

Automation is another key trend. Smarter machines and real-time monitoring help cut down manual work and keep quality consistent. Improved dielectric fluids are also making a difference, enhancing cutting speed and surface finish while reducing wear on electrodes.

Research at HYCNC focuses on pulse optimization and smarter electrode design. By fine-tuning electrical discharges, we improve material removal rates and surface roughness, making the process faster and cleaner.

At HYCNC, we’re committed to leading the way with technology that delivers precision, reliability, and better results for our U.S. customers. Whether it’s through advanced equipment or ongoing innovation, we make sure our EDM machining services meet the demands of tomorrow’s manufacturing challenges.