Introduction to Metal Etching

What Is Metal Etching

Metal etching is a precise and controlled process used to create detailed designs, patterns, or components on metal surfaces. It involves removing layers of metal through chemical, photochemical, or CNC metal etching techniques to achieve specific shapes or markings. This method allows for intricate cuts and fine details that other manufacturing processes might struggle to produce.

Why Metal Etching Matters for Your Business

Metal etching plays a critical role in various industries, offering businesses a way to create custom metal parts, precision metal components, and high-quality etched metal plates efficiently. Whether you need microfabrication etching for electronics, industrial etching applications for manufacturing, or artistic designs, metal etching provides accuracy and flexibility that can greatly improve your product quality.

Choosing the right metal etching service can reduce costs, speed up production times, and help maintain consistency across batches. It’s a reliable solution that supports eco-friendly metal etching practices, ensuring your business meets both environmental standards and customer expectations. At HYCNC, we understand how important these factors are and tailor our services to meet your unique needs.

The Metal Etching Process Explained

Metal etching is a precise way to create detailed designs or parts by removing layers of metal using a chemical or photochemical etching process. At its core, metal etching starts with a protective mask applied to the metal surface. Areas not covered by the mask are exposed to an etching solution that dissolves the metal, leaving behind the desired pattern or component.

How Metal Etching Works

- Design Preparation – Your design is transferred onto a metal sheet using a photoresist or mask.

- Etching – The metal is exposed to a chemical solution that selectively eats away the unprotected parts.

- Cleaning – The mask is removed, revealing the etched metal with sharp, accurate details.

This process allows for high precision without the heat or mechanical force involved in other methods, minimizing distortion.

Materials Suitable for Etching

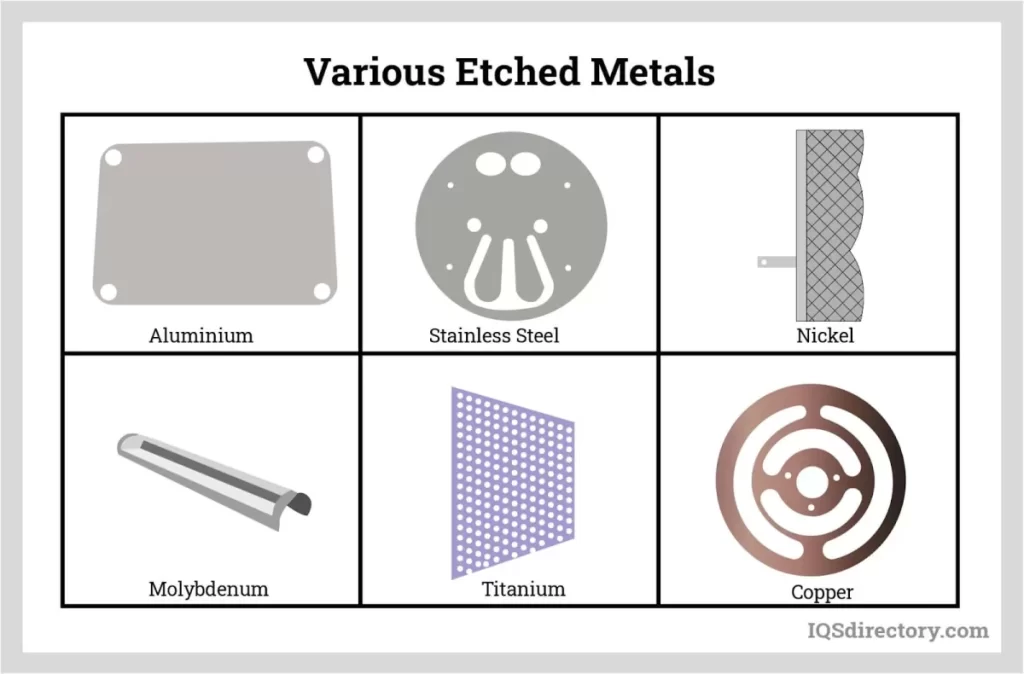

Metal etching works broadly with:

- Stainless steel

- Aluminum

- Copper

- Brass

- Nickel alloys

Each metal reacts differently in the etching solution, making it ideal for a wide range of applications — from industrial parts to custom engraved plates.

HYCNC’s Advanced Etching Technology

At HYCNC, we use state-of-the-art CNC metal etching combined with photochemical etching methods. This ensures:

- Consistent Precision for microfabrication etching on small parts

- Fast Turnaround Times to meet your project deadlines

- Eco-Friendly Etching Solutions minimizing chemical waste

- Versatility across different metals and complex designs

Our technology helps produce high-quality, durable products whether you need precision metal components or custom metal parts for industrial or decorative uses.

Benefits of Metal Etching with HYCNC

Choosing metal etching with HYCNC means you get precision and accuracy every time. Our advanced CNC metal etching technology ensures your custom metal parts and etched metal plates are detailed exactly as you need, down to the finest microfabrication etching details.

We also deliver cost-effective solutions. Compared to other fabrication methods like stamping or laser cutting, photochemical etching reduces waste and tooling costs, making it ideal for both small and large runs without breaking the bank.

Our process is versatile, working well with a variety of materials from stainless steel to copper and aluminum. This flexibility supports everything from industrial etching applications to artistic designs.

Sustainability is key at HYCNC. Our eco-friendly metal etching process uses fewer chemicals and generates less waste, helping your business reduce its environmental impact.

Lastly, we pride ourselves on a fast turnaround. Whether you need prototypes or full production, we keep your project on schedule without sacrificing quality. This speed helps you stay competitive in today’s market.

For a complete metal solution, check out our metal bending services that complement our etching capabilities perfectly.

Applications of Metal Etching

Industrial Applications

Metal etching is a go-to for many industries that need precise, durable parts. From aerospace components and automotive parts to electronics and medical devices, etched metal parts provide the exact specifications needed without extra machining. The chemical etching process delivers high precision, making it ideal for creating microfabrication etching and custom metal parts used in manufacturing lines.

Artistic and Decorative Uses

Beyond industrial uses, metal etching shines in art and design. It allows for detailed and intricate patterns on metal surfaces, perfect for decorative panels, signage, and even personalized gifts. Whether it’s etched metal plates for awards or unique jewelry designs, the flexibility of metal etching brings creativity to life with a professional finish.

HYCNC’s Industry-Specific Solutions

At HYCNC, we tailor our metal etching services to fit your industry’s exact needs. Whether you need precise CNC metal etching for industrial applications or decorative finishes, our advanced, eco-friendly metal etching techniques deliver consistent quality and fast turnaround. Plus, we coordinate with other metal services, like metal bending, for a one-stop solution that aligns perfectly with your project timelines and specifications.

Explore how our metal bending services work hand-in-hand with our etching capabilities to offer you comprehensive metal processing solutions.

Why Choose HYCNC for Metal Etching Services

When it comes to metal etching, choosing the right partner makes all the difference. Here’s why HYCNC stands out:

Expertise and Experience

We bring years of know-how in CNC metal etching and photochemical etching processes. Our skilled team ensures every custom metal part meets your exact specs, delivering precision metal components you can trust.

Local and Global Reach

Based in the U.S., we serve local businesses and clients worldwide. Whether you need small-batch microfabrication etching or large industrial etching applications, we have the capacity to handle your project efficiently.

Customer-Centric Approach

Your goals are our priority. We work closely with you from design consultation through to final delivery. Our communication is clear, and our team is ready to adapt to your changing needs.

Quality Assurance

At HYCNC, quality isn’t just a checkbox—it’s our standard. We use advanced CNC machining and chemical etching processes combined with stringent controls to ensure every etched metal plate or part performs flawlessly.

Ready to see how our metal etching services can help your business? Contact us today for a quote or a free design consultation.

For related metal fabrication solutions, check out our metal bending services.

Comparing Metal Etching to Other Methods

Etching vs Laser Cutting

Laser cutting is great for quick cuts and complex shapes, but it can sometimes cause heat damage or rough edges on thin metals. Metal etching, especially chemical or photochemical etching like what HYCNC offers, provides smoother, more precise edges without warping. Etching is ideal when you need detailed, delicate designs or microfabrication etching, which laser cutting often can’t handle as cleanly.

Etching vs Stamping

Stamping is cost-effective for large runs and simpler shapes but falls short on precision and customization. It also requires expensive tooling and setup. Metal etching shines when you want intricate, custom metal parts or lower-volume projects without the upfront costs. Plus, etching delivers consistent fine details for complex industrial etching applications.

Why HYCNC’s Etching Stands Out

- Precision metal components: We use advanced CNC metal etching to deliver consistent, high-accuracy results.

- Eco-friendly metal etching: Our methods reduce waste compared to traditional cutting or stamping.

- Versatility: Whether you need etched metal plates, custom metal parts, or microfabrication etching, we handle it all.

- Fast turnaround: We understand business needs and deliver quality work on tight schedules.

Choosing HYCNC means you get reliable, cost-effective metal etching services that fit your project, whether it’s industrial, decorative, or specialty use.

How to Get Started with HYCNC

Getting started with HYCNC for metal etching is simple and straightforward. Here’s how you can begin:

Request a Quote

Reach out through our website or call us to get a custom quote for your metal etching project. Provide details about your design, quantity, and material to get an accurate price.

Design Consultation

If you need help with your design or want to optimize it for the chemical etching process, our experts are ready to assist. We’ll guide you through any adjustments to ensure the best results.

Local Search Optimization

We serve businesses across the U.S., offering fast turnaround times thanks to our strategically located facilities. Finding us online is easy—we rank well for local metal etching services so you can connect quickly with a nearby partner.

Next Steps

Once you approve your quote and design, we start production using our advanced CNC metal etching technology. You’ll receive updates during the process, and we handle shipping promptly so your project arrives on time.

Partnering with HYCNC means you get professional, eco-friendly metal etching services that meet your needs right here in the U.S. Contact us today to kick off your project!