What is Injection Mold Tooling

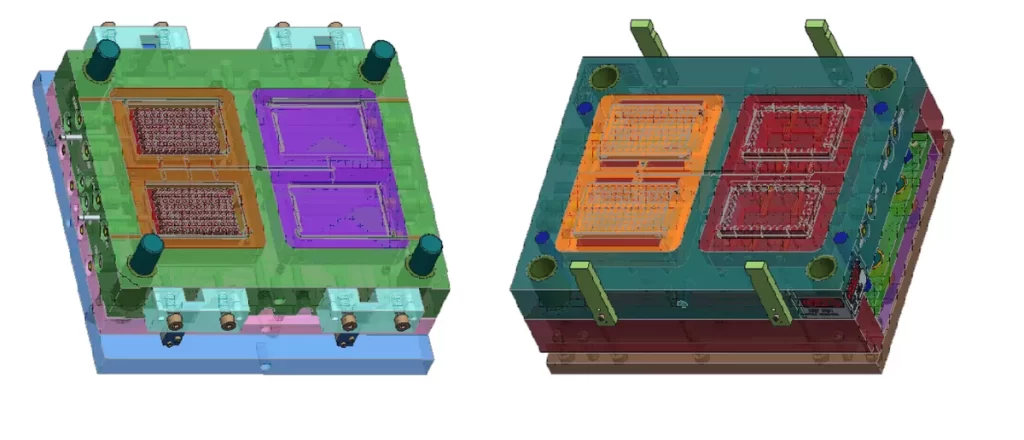

Injection mold tooling refers to the custom-made molds used in the injection molding process to shape molten plastic into precise parts. These molds consist of key components including the cavity, which forms the outside shape of the part, and the core, which creates internal features. Other essential elements include runners and gates, which channel the molten plastic into the mold cavities, and ejector pins that push the finished part out after it cools and solidifies.

The quality of injection mold tooling directly impacts precision, consistency, and efficiency during production. Well-crafted molds ensure each part meets exact specifications, reduce waste from defects, and speed up manufacturing cycles. That’s why investing in quality tooling is crucial for achieving reliable, high-volume production runs with uniform results.

Types of Injection Mold Tooling

Injection mold tooling comes in different types to match your production needs. Here’s a quick rundown:

-

Single-cavity molds: Perfect for prototyping and low-volume runs. These molds produce one part per cycle, making them ideal when you need fast, cost-effective testing.

-

Multi-cavity molds: Designed for high-volume production, these molds create multiple identical parts in each cycle. This boosts efficiency and lowers the cost per part.

-

Family molds: These molds produce several different parts in one cycle. They’re great when you want multiple components for an assembly without running separate molds.

-

Insert molds: Used to integrate metal parts or other inserts into plastic during molding, combining materials seamlessly.

-

Overmolding: This process adds a second layer or texture over a base part. It’s common for ergonomic grips or multi-material designs.

At HYCNC, we specialize in designing and manufacturing all these mold types. Using advanced CNC machining, we ensure precision and flexibility no matter the complexity or volume you need.

Materials for Injection Mold Tooling

Injection mold tooling relies on the right materials to ensure durability, precision, and cost-effectiveness. Common steel types like P-20, S-7, and H-13 are popular for their toughness and wear resistance, making them ideal for long production runs and harsh conditions. For quicker, lighter, and more affordable options, aluminum is often chosen, especially during prototyping or low-volume runs where speed and cost savings matter most.

We also work with specialty materials like MoldMAX and copper alloys. These materials improve thermal conductivity, helping molds cool faster and reducing cycle times. This means better efficiency without sacrificing quality.

At HYCNC, we carefully select materials based on your project’s unique demands. Our goal is to strike the perfect balance between mold life, production volume, and budget, ensuring you get the most value from your injection molding tooling.

Learn more about our full range of injection molding services here.

Key Considerations in Injection Mold Tooling Design

When designing injection mold tooling, several key factors come into play to ensure the final product meets quality and production needs.

Part Geometry

Complex shapes often need special features like sliders or lifters. These help create undercuts or tricky details without compromising the mold’s functionality or the part’s integrity.

Gate Placement

Where you place the gate is critical. Proper gate positioning leads to uniform filling of the mold, which helps avoid defects like short shots, sink marks, or warping.

Cooling Systems

Efficient cooling channels are essential. They reduce cycle times and improve the overall quality of the parts by controlling the temperature during molding, preventing issues like warping or uneven shrinkage.

Mold Flow Analysis (MFA)

At HYCNC, we use mold flow analysis software to optimize how plastic flows inside the mold. MFA helps spot and fix potential weld lines, air traps, or uneven fillings before the mold is made, saving time and reducing defects.

Precision CNC Machining

Tight tolerances and consistent molds are a must for high-quality parts. Our advanced CNC machining ensures the mold components are made with exact precision, yielding better parts and smoother production runs.

By considering all these factors, HYCNC delivers injection mold tooling that balances quality, efficiency, and durability for your project needs.

Benefits of Injection Mold Tooling with HYCNC

When you choose HYCNC for injection mold tooling, you get precision that stands up in high-volume production. Our tight tolerances make sure every part fits perfectly and performs consistently.

We also help you save money. By optimizing mold design, we cut down defects and reduce cycle times, which means less wasted material and faster production runs.

Durability is another big plus. We use top-quality tool steel and advanced materials that hold up even when molding abrasive plastics, ensuring your molds last longer and deliver reliable results over time.

Need a custom solution? We’ve got you covered. Whether your project involves complex part shapes or works for specific industries like automotive or medical, we tailor each mold to your exact needs.

Finally, speed matters—our advanced CNC machining and prototyping capabilities deliver fast turnaround times. You’ll get your molds quicker, keeping your production on schedule without sacrificing quality.

Common Challenges and How HYCNC Addresses Them

Injection mold tooling isn’t without its challenges. At HYCNC, we tackle common issues head-on to keep your production smooth and cost-effective.

-

Reducing Defects

Sink marks, warping, and other defects can derail quality. We use advanced mold flow analysis (MFA) to perfect gate placement and cooling system design, ensuring even material flow and faster, consistent cooling. This approach minimizes common molding problems before they happen.

-

Controlling Tooling Costs

Smart material choices are key. We balance durability and cost by selecting the right tool steel or aluminum depending on your project’s volume and complexity. Plus, our prototyping strategies let you test early without breaking the bank, saving money long-term.

-

Handling Complex Geometries

Got a tricky design? Our precision CNC machining and design expertise handle complex shapes with features like sliders or lifters. We make sure your custom mold tooling fits your part perfectly, no matter how detailed it is.

-

Extending Mold Life

Long-lasting molds reduce downtime and keep expenses low. HYCNC offers maintenance services focused on preserving mold integrity, so your tooling performs reliably over extended production runs.

Partnering with HYCNC means fewer headaches and more consistent results from your injection mold tooling.

Why Choose HYCNC for Injection Mold Tooling

At HYCNC, we bring decades of experience in CNC machining and mold design, serving a wide range of industries across the United States. Our deep expertise ensures your injection mold tooling is built right from the start, delivering precision and reliability every time.

We leverage advanced technology like mold flow analysis software and high-precision CNC equipment to optimize mold design and manufacturing. This means fewer defects, faster cycle times, and consistent quality throughout your production runs.

Whether you need custom mold tooling for prototyping, low-volume, or high-volume production, we offer flexible solutions tailored to your project’s needs. Our team works closely with you from the initial design consultation through production and ongoing maintenance to ensure your molds perform flawlessly.

Ready to improve your injection molding process? Contact HYCNC today for a free quote or consultation and see how our expertise can help take your project to the next level.