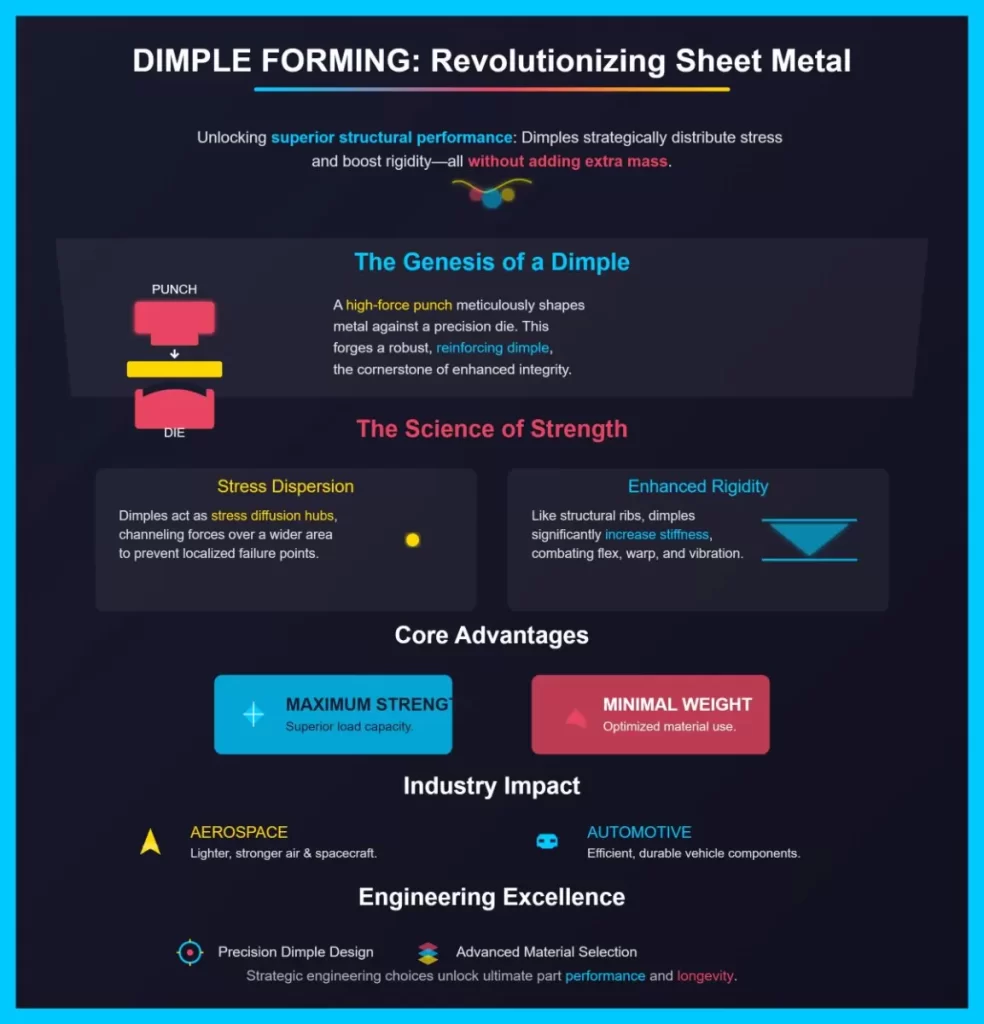

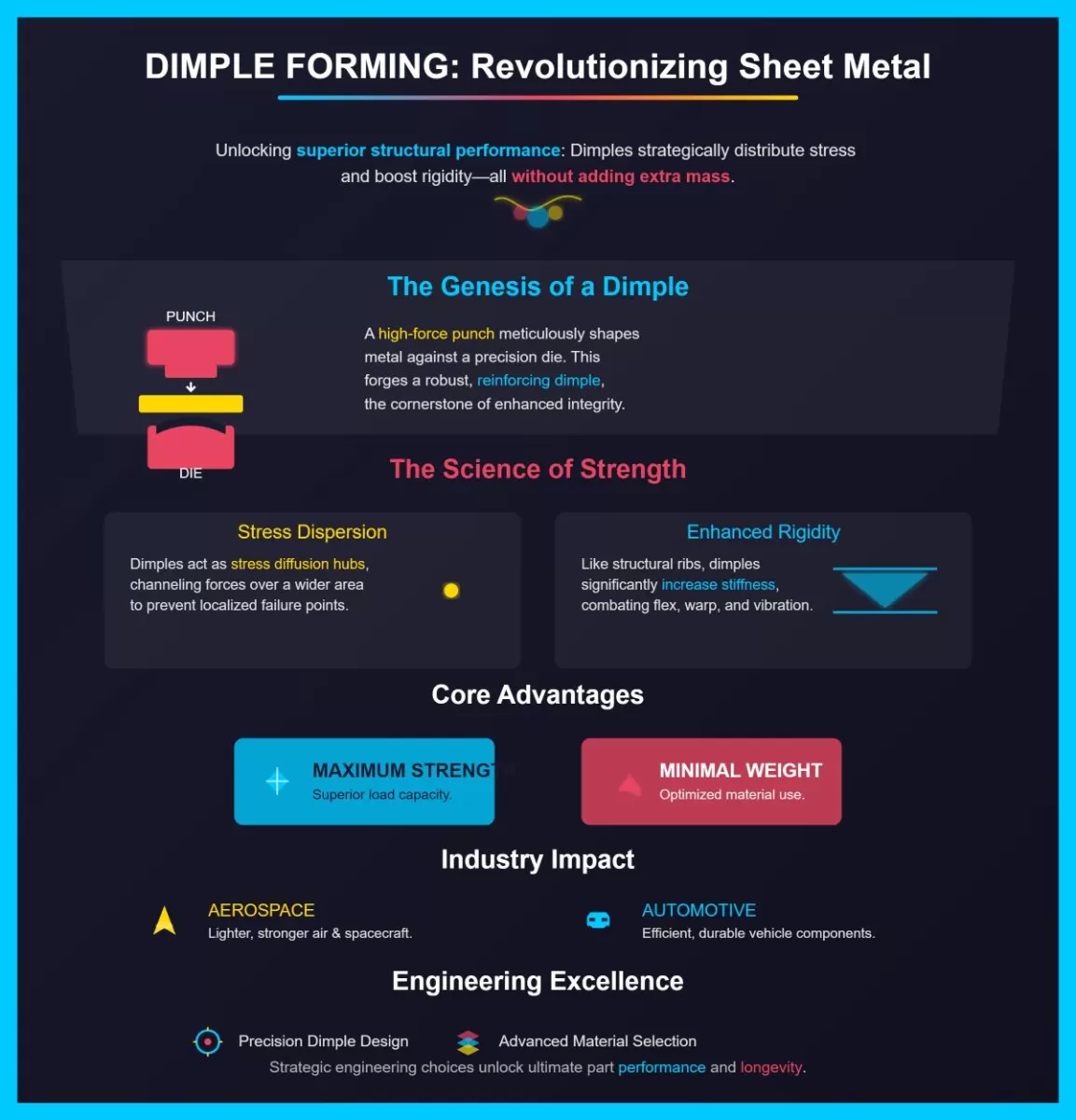

Understanding Dimple Forming Definition and Process

Dimple forming is a metalworking technique that creates small, controlled indentations in sheet metal. These dimples add structural strength without increasing the material’s weight, making the metal both lighter and more durable. Historically, dimple forming gained prominence during World War II when aircraft panels used dimpled aluminum to improve stiffness and reduce airframe weight.

Today, CNC dimple forming takes this process to a new level of precision. Computer Numerical Control (CNC) technology allows for exact placement, size, and depth of each dimple, ensuring consistent quality and performance across the entire sheet. This precision is essential for industries where reliability and strength are critical, like aerospace and automotive manufacturing. Using CNC dimple forming tools, manufacturers can customize dimpling patterns quickly and accurately, resulting in better structural metal strengthening for every project.

Understanding Dimple Forming Key Benefits

Dimple forming boosts material strength without making the metal heavier. By creating small indentations, the sheet metal becomes stronger and more rigid, which means you get better performance without added weight. This is a big win for industries like aerospace and automotive where cutting weight is crucial.

Using dimple forming also helps reduce overall weight in parts, improving fuel efficiency and lowering costs. Plus, it offers more than just strength—dimples can be customized for looks or specific functions, giving you both style and performance in one. Whether it’s improving airflow, adding grip, or enhancing durability, dimple forming adds value beyond traditional sheet metal work.

Understanding Dimple Forming Applications Across Industries

Dimple forming plays a big role in several industries thanks to its ability to add strength and reduce weight. In aerospace, it’s used to make lightweight, durable panels that help planes stay strong without extra bulk. In automotive, dimples add stiffness to structural parts, improving safety while keeping vehicles lighter. General manufacturing also benefits—dimples can improve sound absorption and boost heat transfer in metal parts. Whether it’s aerospace sheet metal or industrial components, dimple forming offers versatile solutions that meet many needs.

Why Choose HYCNC for Dimple Forming Advanced CNC Capabilities

At HYCNC, we use state-of-the-art CNC equipment to deliver precise dimple forming every time. Our advanced machinery allows us to create clean, consistent indentations in sheet metal that meet your exact specifications. Whether you’re working with aluminum, steel, titanium, or other metals, we’ve got you covered.

We also support a wide range of custom dimple sizes, with diameters up to 3 inches. This flexibility helps you get the exact structural benefits and aesthetic look you need for your project. Our precision CNC machining ensures that every dimple is formed accurately, improving strength and performance without adding extra weight.

Why Choose HYCNC for Dimple Forming Fast Turnaround and Competitive Pricing

When you need dimple forming done quickly and reliably, HYCNC delivers in 1 to 3 days. We know tight deadlines are common in aerospace, automotive, and industrial projects, so our team keeps production fast without cutting corners on quality.

Our pricing is straightforward and competitive. You get instant quotes online with no hidden fees, making it easy to budget your sheet metal dimpling job. This combination of speed and clear pricing helps you keep your projects on track and on budget.

Why Choose HYCNC for Dimple Forming Comprehensive CNC Services

At HYCNC, we offer more than just dimple forming. You can combine dimple forming with other CNC services like cutting, bending, tapping, and more, all in one place. This means you get a complete solution for your sheet metal projects without juggling multiple vendors. Whether you need precise dimples, clean cuts, or exact bends, we handle it all with tight quality control. Choosing HYCNC saves you time, simplifies your workflow, and ensures every part fits perfectly with your design needs. For local U.S. customers looking for reliable, custom metal fabrication, HYCNC is your one stop shop for all sheet metal needs.

Why Choose HYCNC for Dimple Forming Local Expertise Global Reach

At HYCNC, we combine local know-how with a global mindset to meet your dimple forming needs. Based in the U.S., we offer fast and reliable delivery to local customers, ensuring your projects stay on schedule without compromising quality.

But our reach doesn’t stop there. We also support global clients with scalable metal forming solutions that adapt to any project size. Whether you’re producing a small batch or managing large-scale production, HYCNC’s flexible services and experienced team have you covered.

By choosing HYCNC, you get the best of both worlds: quick turnaround for American businesses and trusted support for worldwide manufacturing partners. This local expertise paired with global reach makes us a reliable choice for precision CNC dimple forming and other sheet metal services.

How Dimple Forming Works with HYCNC Step by Step Process

Getting your sheet metal ready with dimple forming at HYCNC is simple and fast. Here’s how it works:

- Upload your design: Start by uploading your CAD file or design directly to HYCNC’s easy-to-use online platform.

- Select materials and dimple specs: Choose the metal type you want, like aluminum or steel, then set your dimple size and placement requirements.

- Get an instant quote: Right after submitting your details, you’ll receive a clear quote along with the estimated production timeline.

This streamlined process means no waiting around—just quick, accurate CNC dimple forming tailored to your project’s needs.

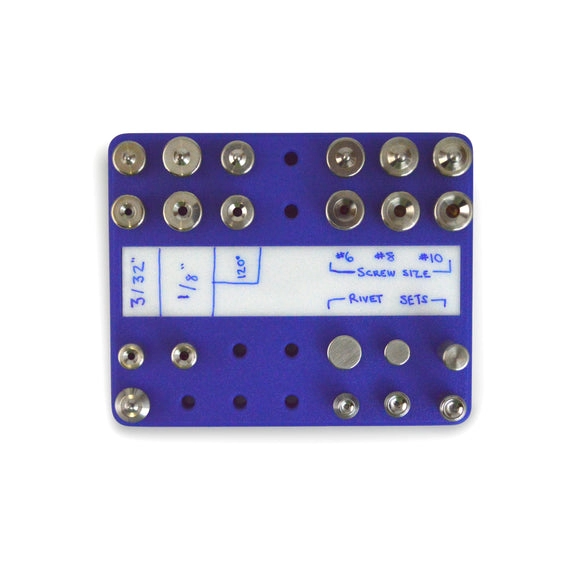

How Dimple Forming Works with HYCNC Supported Materials and Specifications

At HYCNC, we work with a wide range of metals for dimple forming to fit your project needs. That includes aluminum, stainless steel, copper, and more. Whether you need lightweight materials like aluminum for aerospace or durable stainless steel for industrial use, we’ve got you covered.

Dimple sizes vary from as small as 3mm up to 3 inches in diameter. This range lets you customize the indentations to match strength requirements, aesthetics, or functional design.

With our advanced CNC dimple forming tools, we ensure every dimple meets precise size and depth specs. That means consistent quality no matter the metal or size you choose.

How Dimple Forming Works with HYCNC Quality Assurance

At HYCNC, quality comes first in every dimple forming project. We conduct precision checks to ensure each dimple is consistent in depth and perfectly placed according to your design. This attention to detail guarantees structural integrity and reliable performance of your sheet metal parts.

Our process also follows strict industry standards for metal forming services, so you get parts that meet or exceed your expectations. Whether you need dimples in aluminum, steel, or titanium, you can count on HYCNC to deliver uniform, high-quality results every time.

Comparing Dimple Forming to Other Sheet Metal Processes

When working with sheet metal, it’s important to choose the right process for your needs. Dimple forming differs from other methods like countersinking, bending, or embossing in key ways.

Dimple forming vs countersinking

Countersinking creates a conical hole for screw heads to sit flush, mainly for assembly purposes. Dimple forming, on the other hand, creates shallow indentations that strengthen the metal without removing material. So, if you want to boost structural integrity without compromising the sheet, dimple forming is the better pick.

Dimple forming vs bending

Bending reshapes the metal by folding it, which is great for frames or corners. Dimple forming doesn’t change the overall shape but adds rigid points, making the metal more resistant to flexing. Choose dimpling when you want to keep flat panels but need added strength.

Dimple forming vs embossing

Embossing raises or lowers patterns for decoration or branding. While dimple forming also creates indentations, its main goal is functional—improving stiffness and reducing weight. Use embossing for style, dimpling for performance.

When to Choose Dimple Forming

- Need lightweight metal with extra strength

- Working with aerospace, automotive, or industrial panels

- Want precise, consistent indentations without changing sheet shape

- Looking for a cost-efficient process that speeds production

Cost and Efficiency Advantages

Dimple forming uses less material and requires less energy compared to heavy bending or cutting. CNC dimple forming offers fast setup and quick turnaround, saving time and keeping prices competitive. It’s a smart choice when you want tough, lightweight metal parts without added costs.

If you’re comparing options, dimple forming stands out for delivering strength, speed, and savings all in one.

Tips for Optimizing Your Dimple Forming Project

Getting the most out of your dimple forming starts with thoughtful design and clear communication. Here are some practical tips to help you:

- Place dimples strategically: Avoid putting dimples too close to edges or too near each other. Proper spacing keeps your sheet metal strong and prevents warping.

- Choose the right material and thickness: Material type and thickness affect how well dimples form and hold. Aluminum and steel work well, but make sure to pick what fits your project’s strength and flexibility needs.

- Work with HYCNC’s team early: Our experts can help you customize dimple sizes and placement, ensuring the best structural results and fit for your application.

- Consider your end use: Whether for aerospace weight savings or automotive strength, tailoring dimple patterns can enhance performance without adding weight.

- Test prototype samples if possible: Small runs can reveal if your design needs tweaks before full production, saving time and money.

These steps help ensure your dimple forming project looks good, performs well, and meets all your specifications. Let HYCNC guide you through custom solutions that fit your local needs with precision CNC machining capabilities.

FAQs About Dimple Forming

What materials are best for dimple forming

Dimple forming works great with metals like aluminum, stainless steel, copper, and titanium. These materials are flexible enough to form dimples without cracking, making them ideal for strong, lightweight parts.

How does dimple forming improve structural integrity

Creating dimples adds stiffness to sheet metal without extra weight. This means your parts become stronger and more durable, which is why dimple forming is popular in aerospace and automotive projects.

Can HYCNC handle large scale dimple forming projects

Yes, HYCNC has the CNC dimple forming tools and advanced equipment to handle projects of any size, from small prototypes to large production runs. We support custom dimple sizes up to 3 inches in diameter and multiple metal types.

What are the lead times and costs

Typical turnaround for dimple forming is 1 to 3 days, with instant quotes available through HYCNC’s online platform. Pricing is transparent and competitive, making it easy to plan your project budget without surprises.