What is Tube Cutting

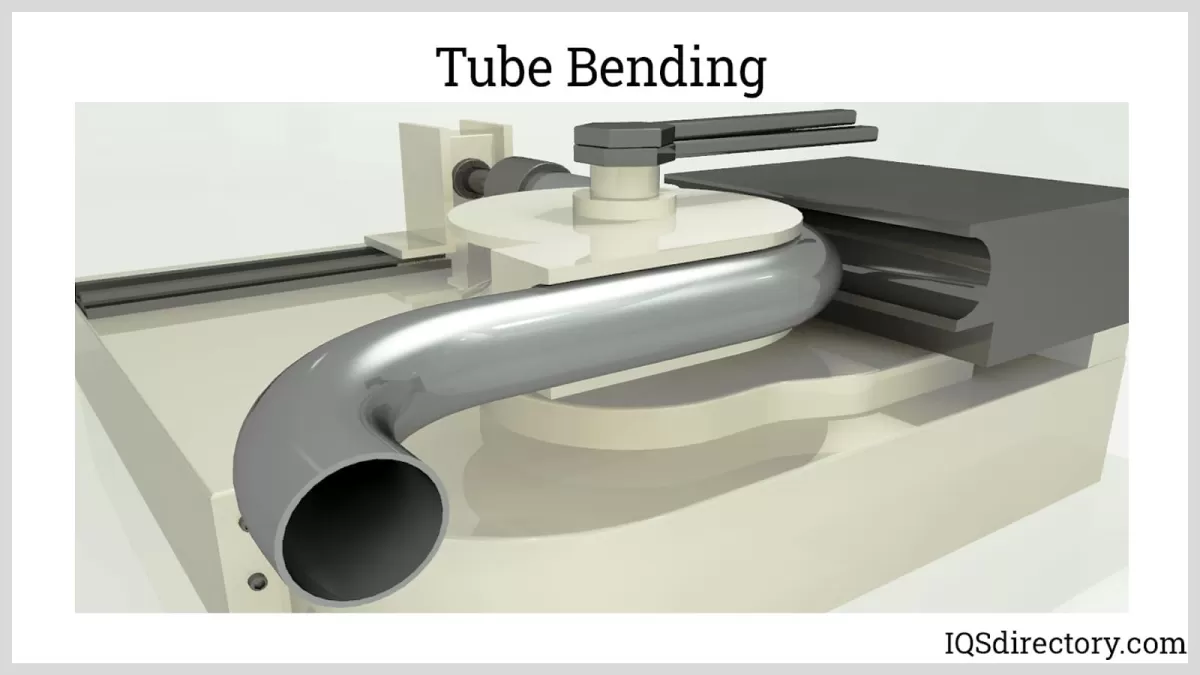

Tube cutting is the precise process of cutting metal or plastic tubes into specific lengths and shapes to meet manufacturing needs. It is a critical step in producing components used across multiple industries, ensuring parts fit perfectly and function reliably.

Definition

Tube cutting involves removing sections from cylindrical materials such as stainless steel, aluminum, or plastic tubing. The process requires accuracy and consistency to maintain the tube’s structural integrity and meet exact specifications.

Applications

Tube cutting plays a vital role in industries like aerospace, automotive, medical devices, and construction. It enables the fabrication of complex parts used in aircraft frames, vehicle exhausts, surgical instruments, and architectural elements.

Why HYCNC for Tube Cutting

At HYCNC, we combine advanced CNC tube cutting technology with expert craftsmanship to deliver unmatched precision and speed. Our tailored solutions accommodate custom dimensions and complex geometries, ensuring every cut meets your exact requirements. Whether you need high-volume production or specialized prototypes, HYCNC’s team and equipment provide reliable, high-quality tube cutting services with fast turnaround times.

Tube Cutting Methods Which is Right for Your Project

When it comes to tube cutting, picking the right method depends on your material, precision needs, and budget. Here’s a quick look at the main tube cutting methods available, so you can decide what fits your project best.

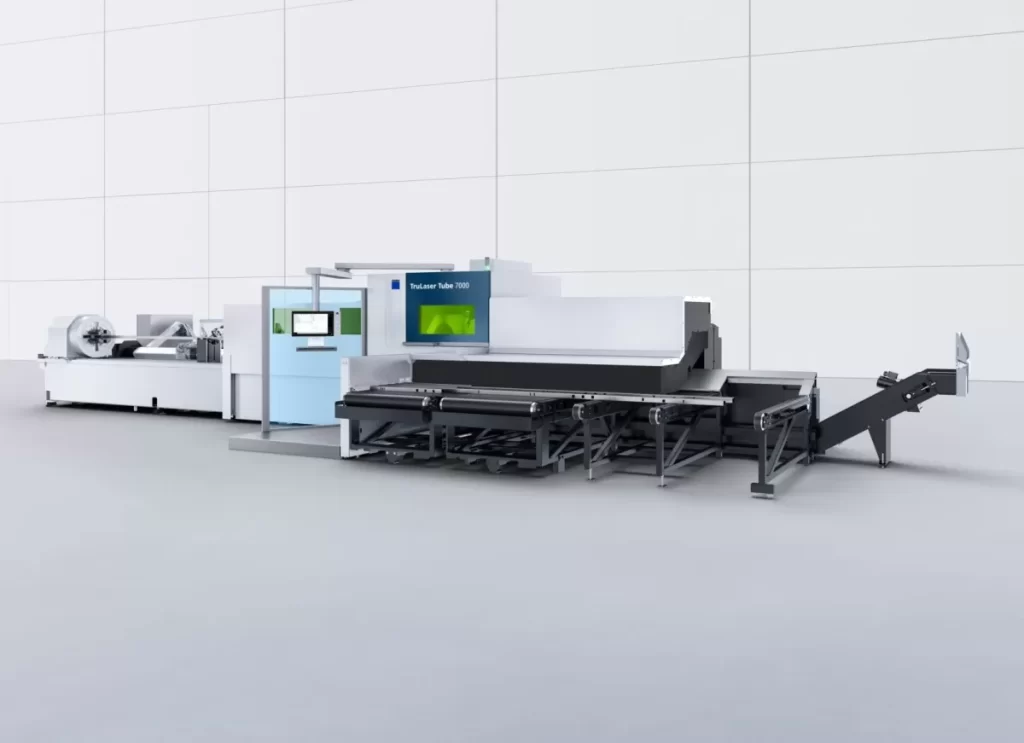

Laser Tube Cutting

- Uses focused laser beams to cut metal tubes with high precision.

- Great for detailed shapes and smooth edges.

- Works best with thin to medium thickness tubes.

- Minimal heat distortion, keeping material integrity intact.

Plasma Cutting

- Uses ionized gas to cut through thicker metal tubes fast.

- Ideal for heavy-duty jobs and thicker metals.

- Lower precision compared to laser but much faster.

- Cost-effective for larger, less detailed cuts.

Waterjet Cutting

- Uses a high-pressure jet of water, sometimes mixed with abrasives.

- Cuts virtually any material without heat distortion.

- Perfect for materials sensitive to heat or where edge quality is critical.

- Can handle thick and complex shapes but generally slower.

Tube Cutting Methods Comparison

| Method | Best For | Precision | Thickness Range | Heat Affected Zone | Speed |

|---|---|---|---|---|---|

| Laser Cutting | Thin to medium metals | Very High | Up to 0.5–1 inch | Minimal | Moderate |

| Plasma Cutting | Thick metals | Moderate | Up to 2 inches+ | High | Fast |

| Waterjet Cutting | Heat-sensitive materials | High | Varies (thick too) | None | Slower |

Why We Recommend HYCNC for Your Tube Cutting Needs

At HYCNC, we specialize in CNC tube cutting that matches your project specs perfectly. Our laser cutting machines offer precision cuts with fast turnaround times, while our expertise in plasma and waterjet gives you flexibility depending on what your project requires. We focus on quality and delivering results that fit your local business needs here in the US.

Why Choose HYCNC for Tube Cutting Services

When it comes to tube cutting services, HYCNC stands out because of expertise, customization, and proven results that fit your project needs.

HYCNC’s Expertise

We specialize in CNC tube cutting using the latest machines and technology. Our team understands precision tube cutting inside and out, delivering clean, accurate cuts every time. Whether it’s metal tube cutting for industrial parts or custom tube cutting for specialized jobs, you’re in expert hands.

Customization for Your Project

At HYCNC, we know every project is unique. That’s why we offer tailored tube cutting solutions that match your exact specifications. From material type to cutting method—laser tube cutting, plasma, or waterjet—we help you choose the best process to optimize quality and budget.

Proven Success with Real Projects

We’ve worked with clients locally and across the U.S., handling projects from automotive components to aerospace tubing. Our case studies showcase how we improve efficiency and cut costs without sacrificing quality. When you work with HYCNC, you get results proven in real-world applications.

Local Support and Fast Turnaround

Being locally based means faster delivery and easier communication. We understand the needs of U.S. businesses and provide quick turnaround times to keep your project on schedule. Our local SEO focus ensures you find us easily when searching for reliable tube cutting services nearby.

Choosing HYCNC means partnering with a focused, experienced team ready to handle your tube cutting challenges with accuracy and care.

Benefits of Precision Tube Cutting for Your Industry

Precision tube cutting offers clear advantages across many industries. Here’s why choosing accurate tube cutting methods matters:

Quality and Accuracy

- Smooth, clean cuts that fit perfectly

- Consistent dimensions reduce errors in assembly

- Better welds and connections with precise edges

Efficiency

- Fast processing speeds help meet tight deadlines

- Less material waste thanks to exact cuts

- Streamlined production lowers downtime

Cost Savings

- Fewer mistakes mean less rework and scrap

- Lower labor costs as machines handle complex cuts

- Long-term savings from durable, high-quality parts

Industry-Specific Benefits

- Aerospace: High precision supports strict safety and performance standards. Precision tube cutting ensures components meet exact specs for airframes and engines.

- Automotive: Fast, repeatable cuts improve production lines for exhausts, frames, and roll cages. This enhances vehicle safety and reliability.

- Medical: Clean, accurate cuts help produce safe and reliable instruments, implants, and hospital equipment meeting strict sanitation and quality controls.

At HYCNC, we specialize in delivering precise CNC tube cutting services tailored for these industries, helping you stay competitive and on schedule.

How to Choose a Tube Cutting Service Provider

Picking the right tube cutting service provider can make all the difference in your project’s success. Here are the key factors to keep in mind:

Experience and Technology

Look for a provider with solid experience in CNC tube cutting and access to the latest machines. Advanced technology means better precision and faster turnaround.

Material Versatility

Your provider should handle a wide range of materials—from stainless steel and aluminum to specialized alloys. This ensures they can meet your specific metal tube cutting needs.

Turnaround Time and Scalability

Fast delivery is crucial, especially for tight deadlines. Also, choose a partner who can scale production up or down based on your project size without sacrificing quality.

Certifications

Certifications like ISO or industry-specific approvals show the provider meets quality and safety standards. This is especially important for sectors like aerospace and medical.

HYCNC Advantage

At HYCNC, we combine local expertise with advanced CNC machining technology. We customize tube cutting solutions to fit your unique requirements, ensuring precision and reliability every time.

When you choose HYCNC, you get a trusted local partner ready to handle everything from custom tube cutting to large industrial orders with top-notch quality and service.

FAQs About Tube Cutting

Here are some common questions we get about tube cutting, especially for customers in the U.S. looking for reliable local services.

What materials can you cut?

We handle a wide range of materials including stainless steel, aluminum, copper, brass, and various metals used across industries like aerospace and automotive.

How does laser tube cutting compare to traditional methods?

Laser cutting offers higher precision and cleaner edges than traditional saw or shear cutting. It’s fast and great for complex shapes, while traditional methods might suit simpler jobs or thicker tubes.

What’s the typical turnaround time?

Turnaround depends on the project size and complexity but at HYCNC, we aim to deliver quick, efficient service without compromising quality. Small to medium runs usually get completed within days.

Can I order small or custom quantities?

Absolutely. Whether you need one custom piece or a large batch, HYCNC accommodates orders of all sizes with the same attention to detail.

What makes HYCNC’s tube cutting services stand out?

Our expertise in CNC tube cutting, advanced machinery, and local customer support ensures precise cuts, fast delivery, and tailored solutions that fit your project needs perfectly.

Get Started with HYCNC Tube Cutting Services

Ready to take your project to the next level with precision tube cutting? At HYCNC, we specialize in custom CNC tube cutting services tailored to your needs. Whether you need laser tube cutting or metal tube cutting for aerospace, automotive, or medical industries, we’ve got you covered.

- Fast turnaround times to keep your project on schedule

- Competitive pricing without sacrificing quality

- Local service and support you can rely on

Contact us today to get a free quote or learn more about how our industrial tube cutting solutions can boost your business. Visit our service page or call us now to speak with an expert.

HYCNC is your trusted partner for precise, efficient, and affordable tube cutting right here in the United States. Get the job done right with us.